About us

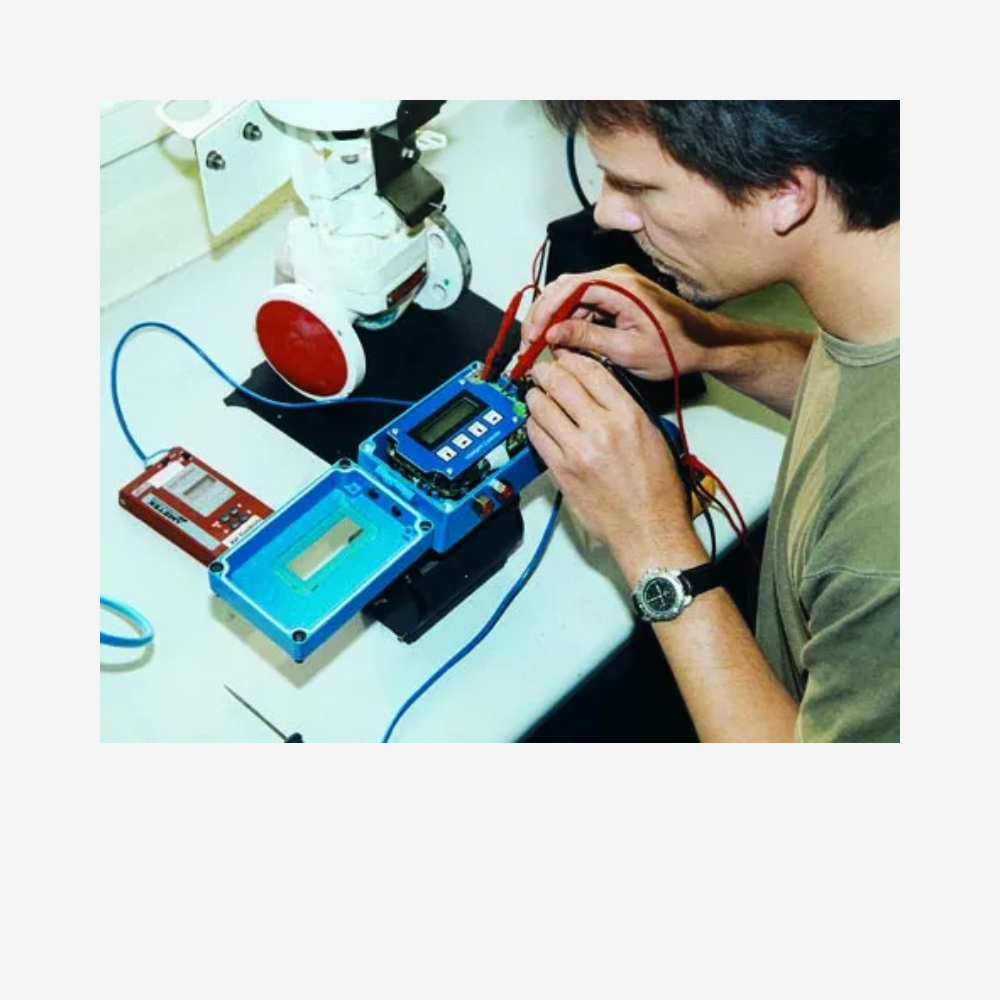

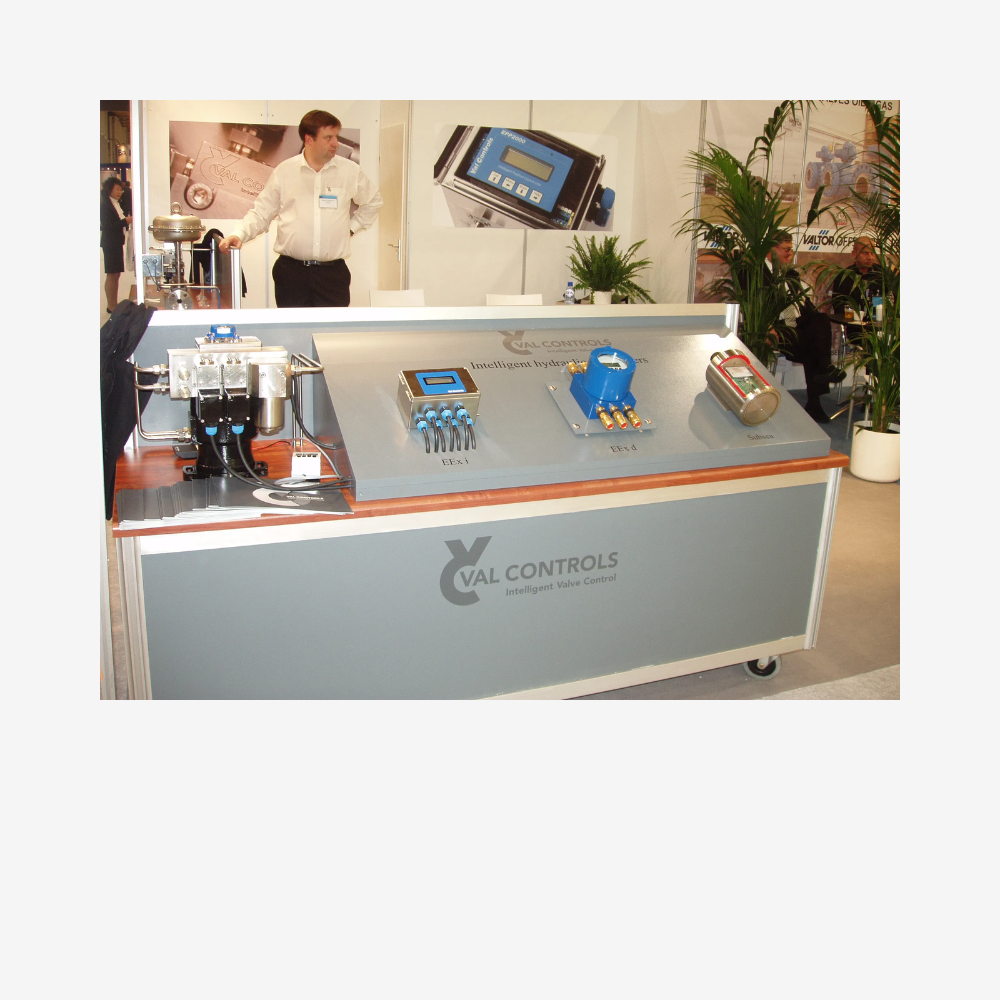

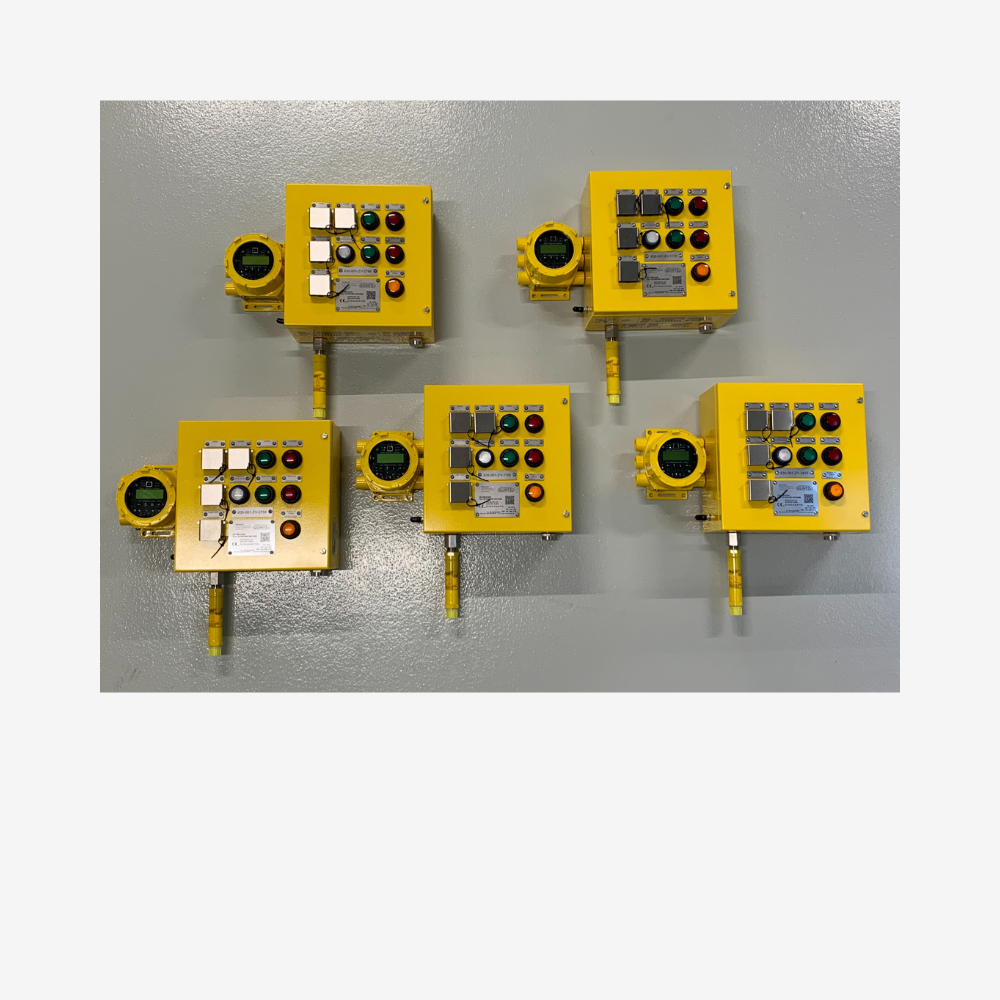

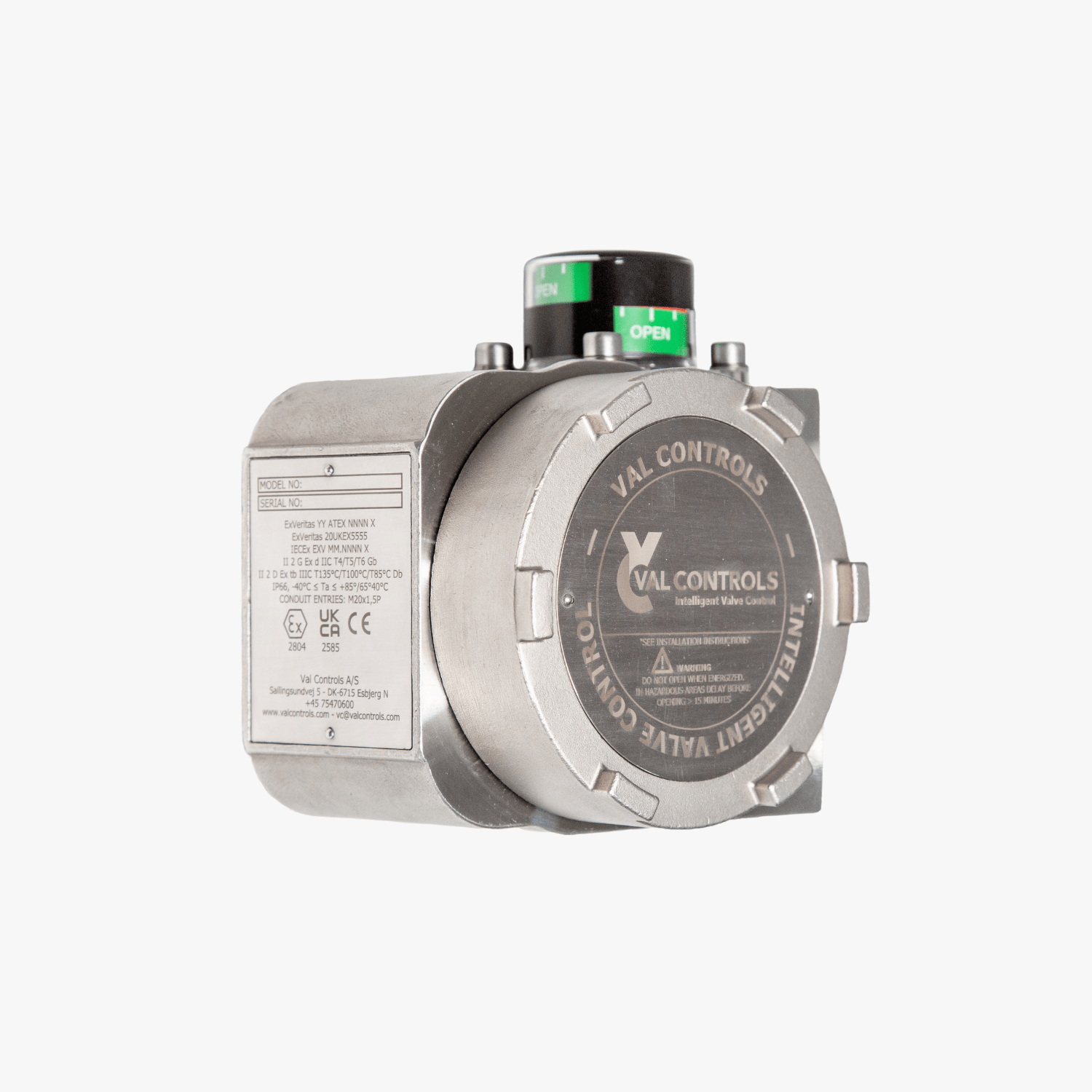

Val Controls A/S specializes in the development and manufacturing of intelligent valve controllers and positioners.

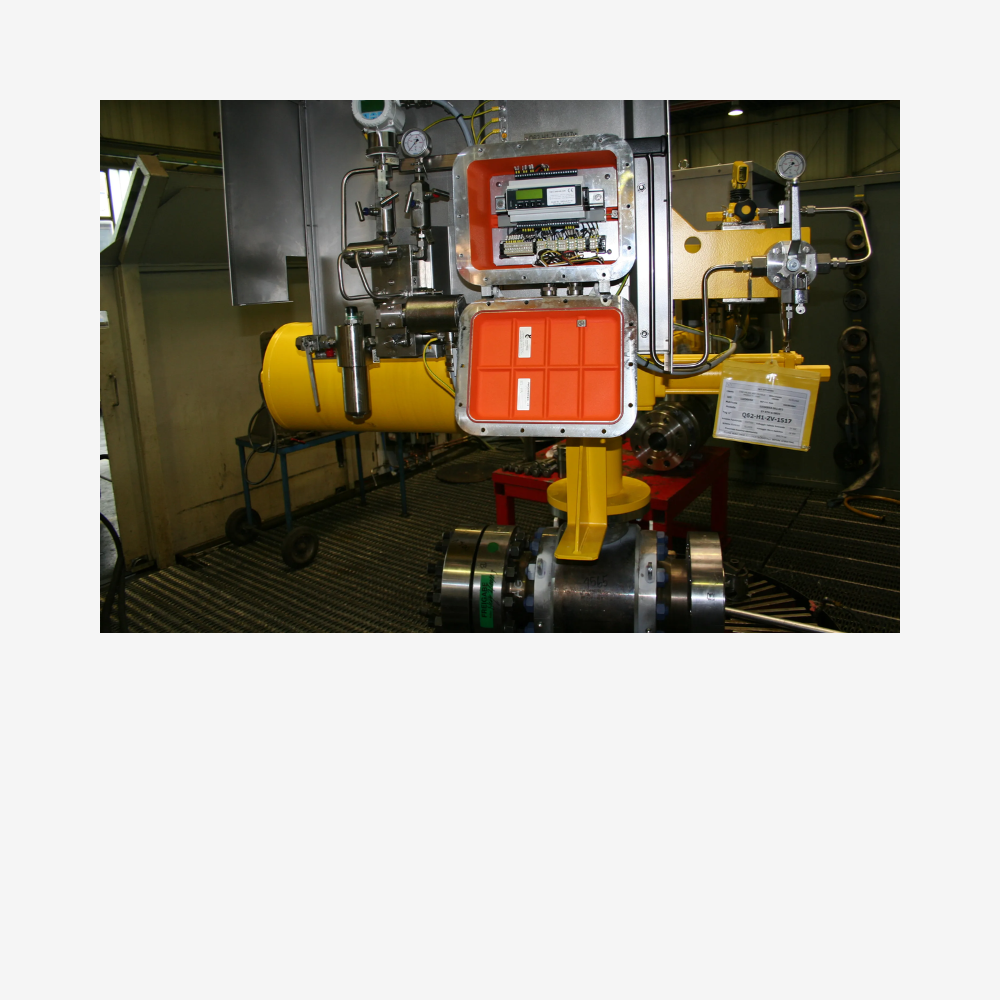

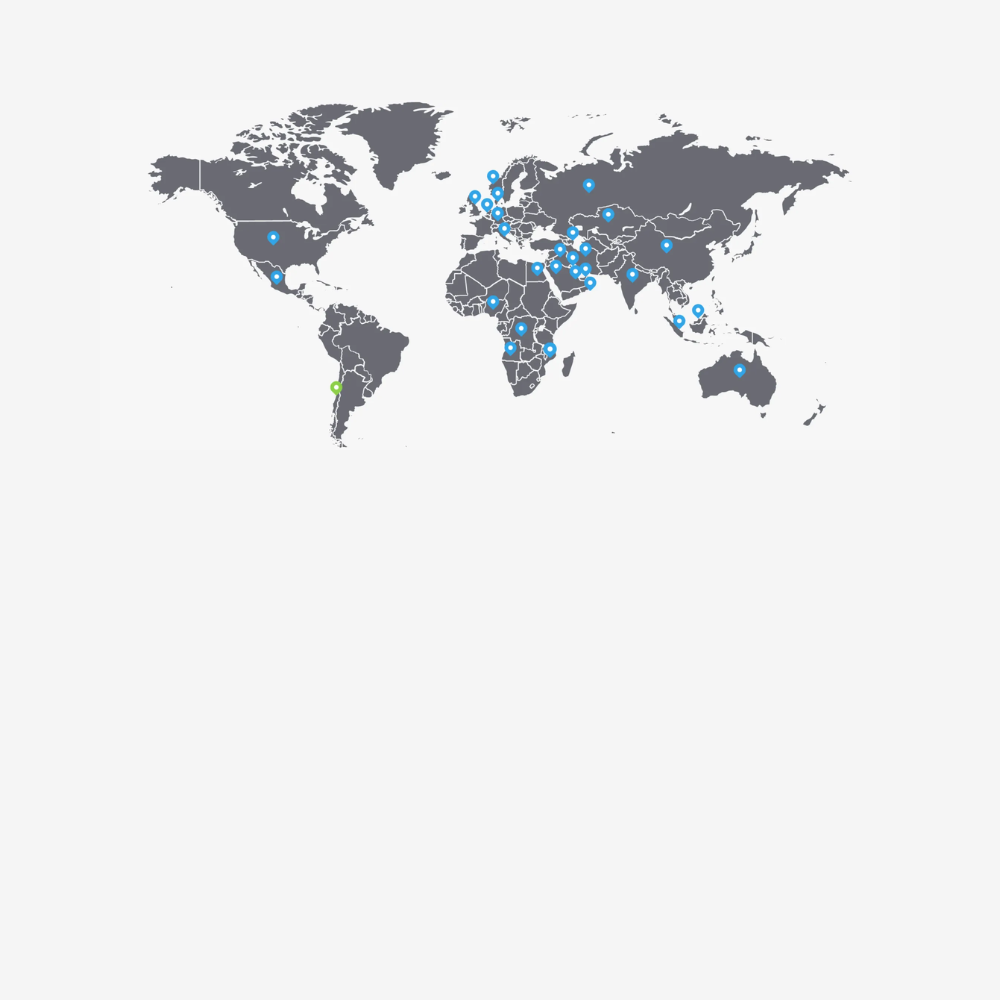

All our products are field-proven and trusted by major end-users worldwide in industries such as Oil & Gas, Water Treatment, Bulk Material Handling, Power Generation, and other industrial applications. Our products often control highly critical valve systems, typically located in Ex areas, making them applicable across a wide range of industries.

Reliability is at the core of everything we do at Val Controls. We understand that our customers’ facilities rely on safe and uninterrupted operations. With decades of experience in developing valve controllers and positioners for critical valve systems, Val Controls is your dependable partner for all valve control and positioning needs.

Vision

To make the world’s best positioners and controllers for hydraulic valve systems.

Mission

With a customer-centric approach, we strive to create valve controllers and positioners that enable our customers to operate their critical valve systems in the safest, most efficient, and environmentally friendly way possible.

Vision

To make the world’s best positioners and controllers for hydraulic valve systems.

Mission

With a customer-centric approach, we strive to create valve controllers and positioners that enable our customers to operate their critical valve systems in the safest, most efficient, and environmentally friendly way possible.

Company Values

Serving a wide range of customers

Based on decades of experience and expertise, we aim to deliver the best results for our customers through long-term and close customer relations. Our main customer base includes:

- Industrial automation distributors

- Actuator manufacturers

- Valve manufacturers

- Valve automation centers

- Hydraulic automation centers

- Industrial hydraulic professionals

Quality policy

We wish to be known as a credible and competent partner for our customers and suppliers. We want to be considered an innovative company having the human and the financial strength to be a responsible partner offering a good service.

Our quality policy is to ensure that:

• We meet demands and expectations from our customers.

• Our core and support processes are working well and efficiently.

• Our suppliers meet our demands and expectations.

• We continuously improve our results and quality control system based on measurements and evaluations.

• We comply with all laws and regulations in Denmark and the countries where we operate.

Environment

At Val Controls, we wish to ensure both the internal and external environment, and we therefore focus on the environmental conditions associated with our activities.

The external environment is affected by the waste we produce from our production and from other activities, and therefore we manage the sorting of the waste so that the subsequent handling and disposal takes place in the most optimal way for the environment.

Wastewater from our processes is reduced and we now have only sanitary wastewater. Similarly, we are continuously working to optimize the consumption of electricity and heat, so that we make the best use of energy.

The internal environmental conditions are monitored through Workplace Evaluations, which the safety organization continuously prepares. Thus, in the safety work, we focus on physical, ergonomic, psychological, chemical, biological and accident hazards, and through action plans we ensure the proper development of internal environmental conditions.

We do every effort to prevent accidents and injuries, and detect, evaluate and learn from the accidents or accidents that almost occur. We wish our employees to experience Val Controls as a good, healthy and safe workplace.