Full Stroke Testing

What is Full Stroke Testing (FST)?

During a Full Stroke Testing (FST) the Emergency Shutdown (ESD) valve is completely opened or closed during the test. The Full Stroke Test is conducted during planned shutdowns, before installation of the valve system or at Factory Acceptance tests (FAT). In these scenarios it is often a requirement to do a Full Stroke Test as a proof test of the valve system.

Full Stroke Testing validates the entire stroke of the valve and is necessary in order to test if the valve will close fully in case of an emergency shutdown (ESD).

Val Controls provides Intelligent Diagnostic Controllers (IDC24) which can perform Full Stroke Testing, Solenoid Operated Valve Testing and Partial Stroke Testing on all types of valve systems. The testing enables the end-user to collect reliable data of the closing and opening signatures of the ESD valves.

Full Stroke Testing

What is Full Stroke Testing (FST)?

During a Full Stroke Testing (FST) the Emergency Shutdown (ESD) valve is completely opened or closed during the test. The Full Stroke Test is conducted during planned shutdowns, before installation of the valve system or at Factory Acceptance tests (FAT). In these scenarios it is often a requirement to do a Full Stroke Test as a proof test of the valve system.

Full Stroke Testing validates the entire stroke of the valve and is necessary in order to test if the valve will close fully in case of an emergency shutdown (ESD).

Val Controls provides Intelligent Diagnostic Controllers (IDC24) which can perform Full Stroke Testing, Solenoid Operated Valve Testing and Partial Stroke Testing on all types of valve systems. The testing enables the end-user to collect reliable data of the closing and opening signatures of the ESD valves.

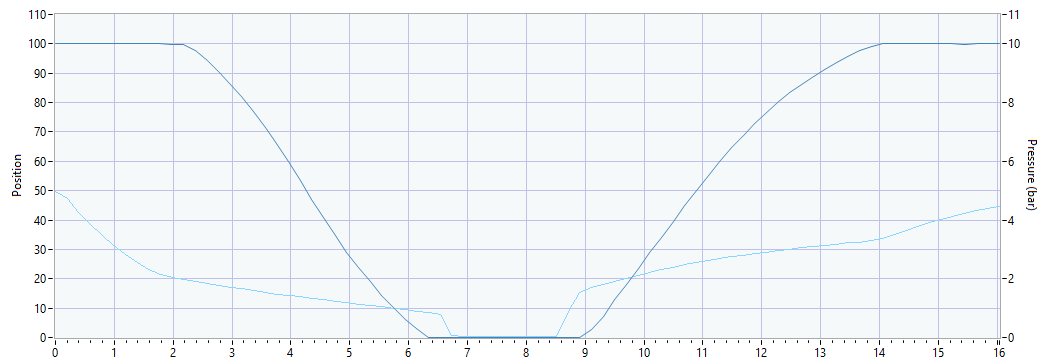

Break away pressure

Breakaway pressure at 2bar.

Full stroke test

FST performed with full signature of position and pressure.

Travel time

Close: 6,26sec.

Open: 5,18sec.

Highlights

Val Controls Full Stroke Testing solution

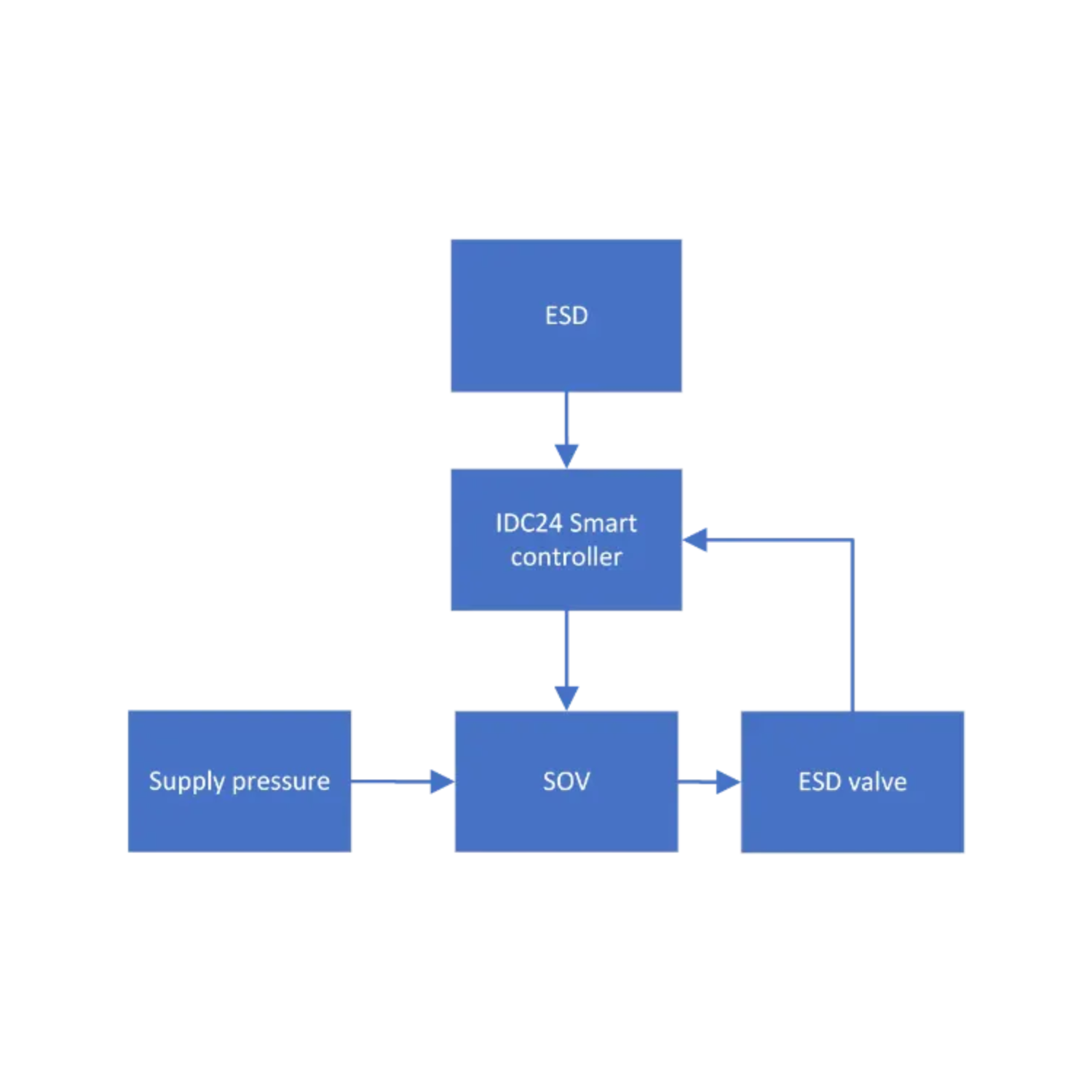

Val Controls FST solution can be used for pneumatic and hydraulic systems and is performed by the IDC24 controller. The IDC24 controller can be used in any environment as well as existing or new installations. Typically, the IDC24 can be added to the system without any need for new cables, extra software etc. making it very easy to install. The Full Stroke Test can be started locally or remote and be customized for the end-user's specifics needs.

The SOV-based solution for Full Stroke Testing, which Val Controls provides can test the complete valve system - including the SOV. Furthermore, it can collect valuable diagnostics information to be used for troubleshooting. The solution is more reliable than the traditional positioner-based solution because it bypasses the supply pressure.

The software provided by Val Controls, allows the end-user to compare data from Factory acceptance test (FAT) and commissioning to present-day data which enables the user to predict when certain parts need replacement or maintenance.