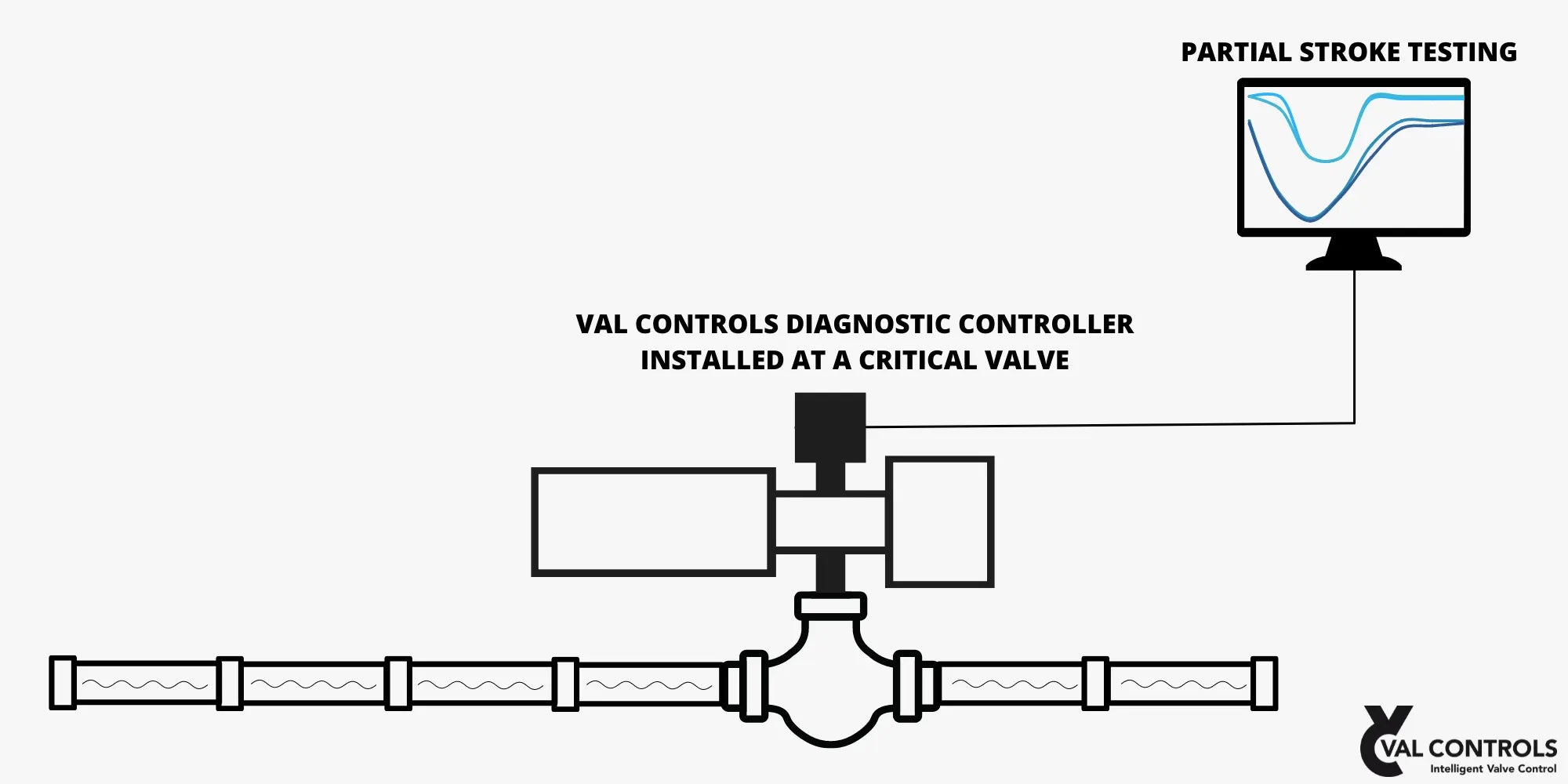

Partial Stroke Testing

What is Partial Stroke Testing (PST)?

The purpose of partial stroke testing is to exercise, and test shut down valves without disturbing the production. The valve will typically be closed 20% for a short time and fully opened again. The test will ensure the valve function is tested and working as required. When Partial Stroke Testing is successfully implemented it offers serval production benefits including an extension between compulsory plant shutdowns and insight in potential valve failures.

Partial Stroke Testing is most often used on high integrity emergency shutdown valves (ESDVs) in applications where closing the valve will have high-cost burden yet proving the integrity of the valve is essential to maintaining a safe facility.

Partial Stroke Testing

What is Partial Stroke Testing (PST)?

The purpose of partial stroke testing is to exercise, and test shut down valves without disturbing the production. The valve will typically be closed 20% for a short time and fully opened again. The test will ensure the valve function is tested and working as required. When Partial Stroke Testing is successfully implemented it offers serval production benefits including an extension between compulsory plant shutdowns and insight in potential valve failures.

Partial Stroke Testing is most often used on high integrity emergency shutdown valves (ESDVs) in applications where closing the valve will have high-cost burden yet proving the integrity of the valve is essential to maintaining a safe facility.

Solenoid reaction time

Solenoid reaction time: 0,31sec.

Overshoot protection

The intelligent software in the IDC24 makes sure the PST will never overshoot.

Val Controls Partial Stroke Testing solution

Benefits of Partial Stroke Testing

Increased safety

If Partial Stroke Testing is successfully implemented the site will receive a higher safety integrity level (SIL). With Val Controls solution the site will typically receive a SIL score of 3, however the IDC24 device is certified up to SIL4. The higher safety integrity level is rewarded because the probability of failure on demand is reduced. During a Partial Stroke Test, the valve will get exercised reducing the risk of stiction, ultimately reducing the risk of malfunction.

Increased production output

The main production benefit of a Partial Stroke Testing, is that the time between compulsory plant shutdowns and required Full Stroke Tests (FST) is extended. Furthermore, data of the Partial Stroke Test can be collected - which can be compared to previous tests - enabling the staff to predict when certain parts need replacement. This method of predictive maintenance allows any upkeep or repairs to be forecasted and scheduled, making procurement and overall plant operation to run more smoothly and efficient.

Val Controls Partial Stroke Testing solution

Partial Stoke Testing for hydraulic and pneumatic valves

- Val Controls Partial Stroke Testing device can be used for pneumatic and hydraulic systems.

- The IDC24 controller can be used in any environment as well as existing or new installations. Typically, the IDC24 can be added to the system without any need for new cables, extra software etc. making it very easy to install.

- The Partial Stroke test can be started locally or remote and be customized for the end-user's specifics needs.

- The IDC24 controller is compatible with 1oo1, 1oo2 and 2oo2 safety instrumented systems.

- The solenoid operated valve (SOV) solution for Partial Stroke Testing, which Val Controls provides can test the complete valve system - including the Solenoid Operated Valve. Furthermore, it can collect valuable diagnostics information to be used for troubleshooting. The solution is more reliable than the traditional positioner-based solution because it bypasses the supply pressure.

- The software provided by Val Controls, allows the end-user to monitor the valve performance enabling you to project at which time the different parts need replacement. This method of predictive maintenance reduces the number of unplanned shutdowns and increases the overall site safety.

Val Controls Partial Stroke Testing solution

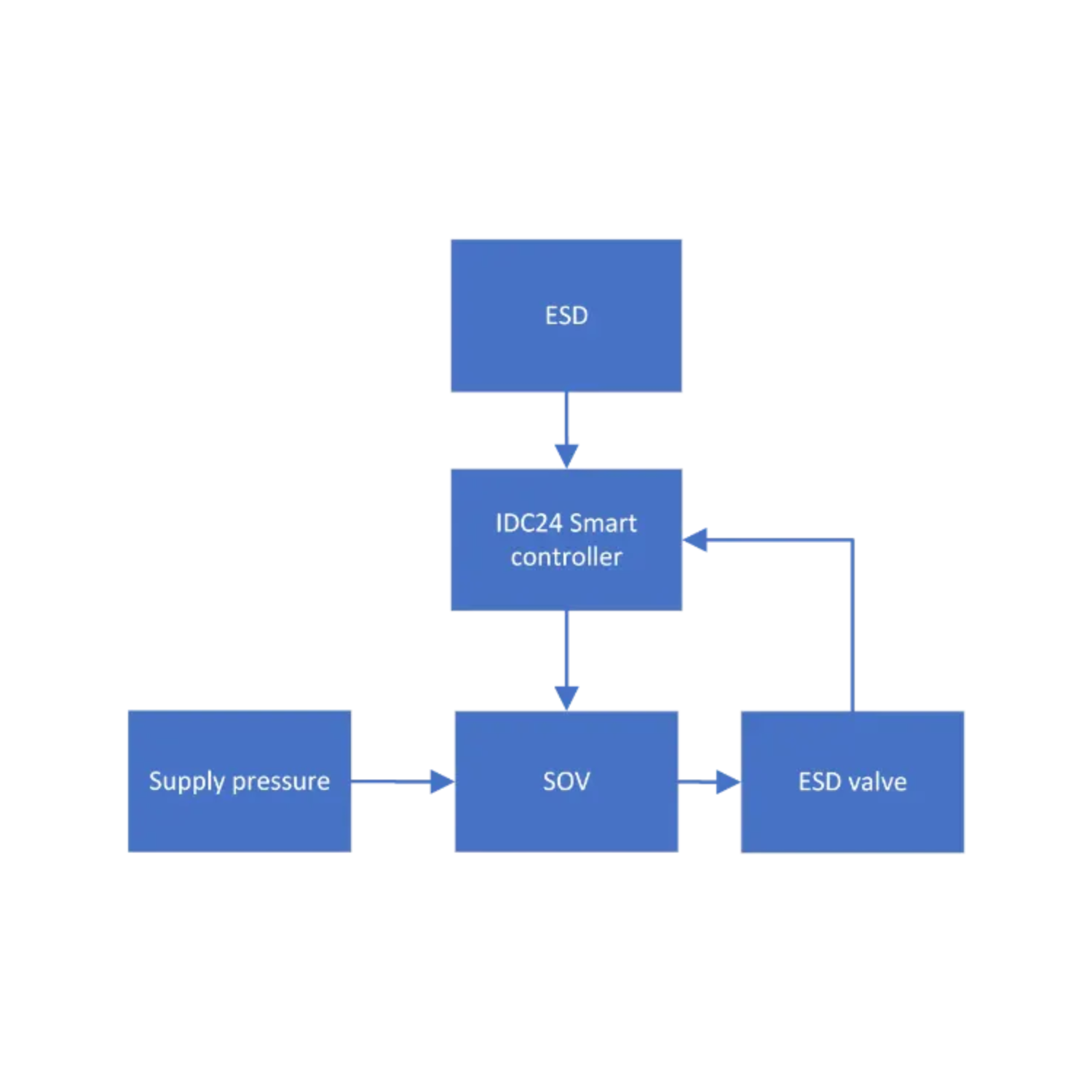

How the Partial Stroke Test is started and data is processed.

1. Test start

The Partial Stroke Test can be started from a Local Control Panel mounted at the valve system or it can be started remotely through the HART or Modbus communication protocols.

2. Data collection

Once a Partial Stroke Test is started, data of the event is collected and stored locally in the IDC24 Controller. Performance data of the event itself will be collected as well as data from a preset period prior to the event.

3. Data extraction

The data can be transferred via HART, Modbus or with USB which allows data of the event to be extracted locally or remotely. It is also possible to install a local control panel which will display an alarm in case of an event.

4. Analysis

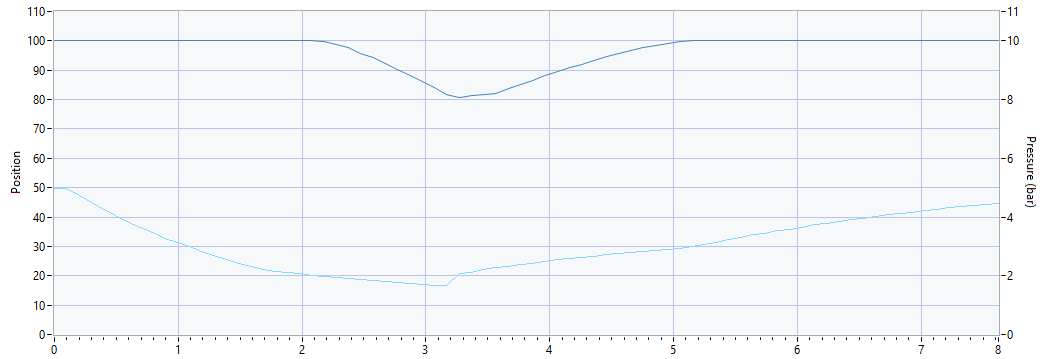

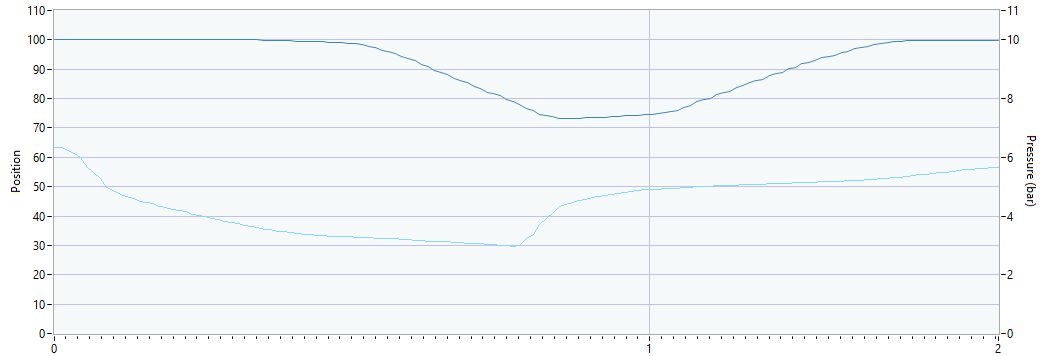

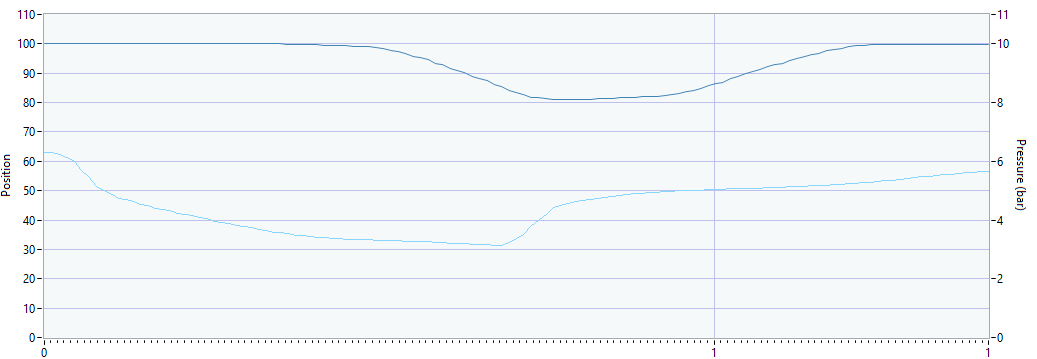

Data of the Partial Stroke Test can be analyzed in Val Controls Diagnostics Centre (VCDC) where it is possible to see the exact time of the event, monitor the pressure and the valve closing performance. The data can be compared to previous events and testing.

Val Controls Partial Stroke Testing solution

Solenoid operated valve (SOV) based Partial Stroke Testing

The SOV-based solution is a simpler and more reliable alternative to the positioner-based solution because it bypasses the supply pressure and does not require additional tubing or wiring. It also has fewer potential failure points because it is installed directly on the actuator, eliminating the need for additional fittings or tubing. The IDC24 controller, which is based on the SOV solution, can be installed directly on the actuator and is not limited by factors such as flow, air quality, or temperature. The flow is only restricted by the capacity of the Solenoid Operated Valve, making the overall setup more reliable and less prone to mechanical failure compared to the positioner-based solution.

Summary: Benefits of SOV-based PST

- No flow restrictions

- No extra fittings or tubings needed

- No air quality restrictions because the supply is only passing through ESD SOV

- Auto-calibration

- Spring return (SR type) compatible

- Double acting (DA type) compatible

- Solenoid Operated Valve testing avialable

- Control panel test available

Partial stroke test overshoot protection

One of the biggest concerns during Partial Stroke test i overshooting. All IDC24 models has overshoot protection as standard.

During auto calibration the IDC24 gathers all information about the systems dynamics, solenoid reaction time, delay in electrical signals etc. It then uses all the information during partial stroke to make sure the system does not overshoot.

Overshoot protection disabled: Movement is 28%.

Overshoot protection enabled: Movement is 20%.