Proportional Solenoid Valve Control

Purpose-built positioners for proportional solenoid valve control

Val Controls' IHP24 range offers two models for controlling proportional solenoid valves: IHP24-A and IHP24-AF. These positioners are compatible with both pneumatic and hydraulic systems and support HART, Modbus, or Foundation Fieldbus communication protocols.

The IHP24-A and IHP24-AF models can operate with either one (1) or two (2) 4-20 mA proportional valves, providing precise control over various applications, such as Linear and rotary actuators, Choke valves, Dampers, Cylinders. The controllers are designed to work with any proportional valve on the market. During automatic calibration, the units adapt the regulator to optimize the performance of the entire system.

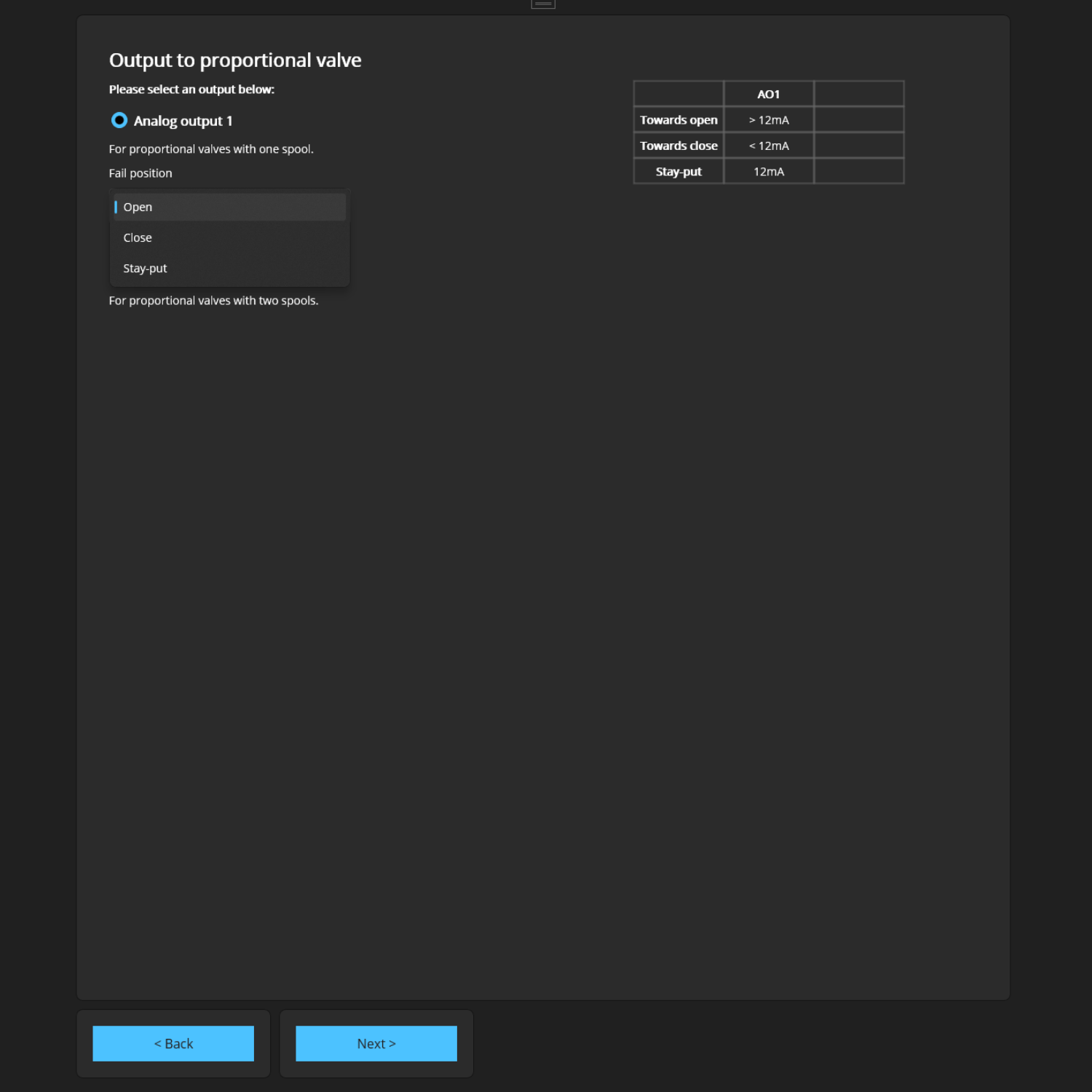

ValConnect

Configuration

Along with the IHP24 unit, a free configuration software is provided, specifically designed to set up and control proportional solenoid valves. This software offers all necessary configuration features, including:

- Whether the system uses a 2- or 4-wire 4-20 mA control signal or a potentiometer.

- Configuration for single or dual-spool proportional solenoid valves.

- The number of locked valves.

- The desired system deadband.

- Speed tuning and stay-put tuning.

Image: Example of ValConnect configuration software

IHP24-A

DIN-rail mounted positioner for proportional solenoid valve control.

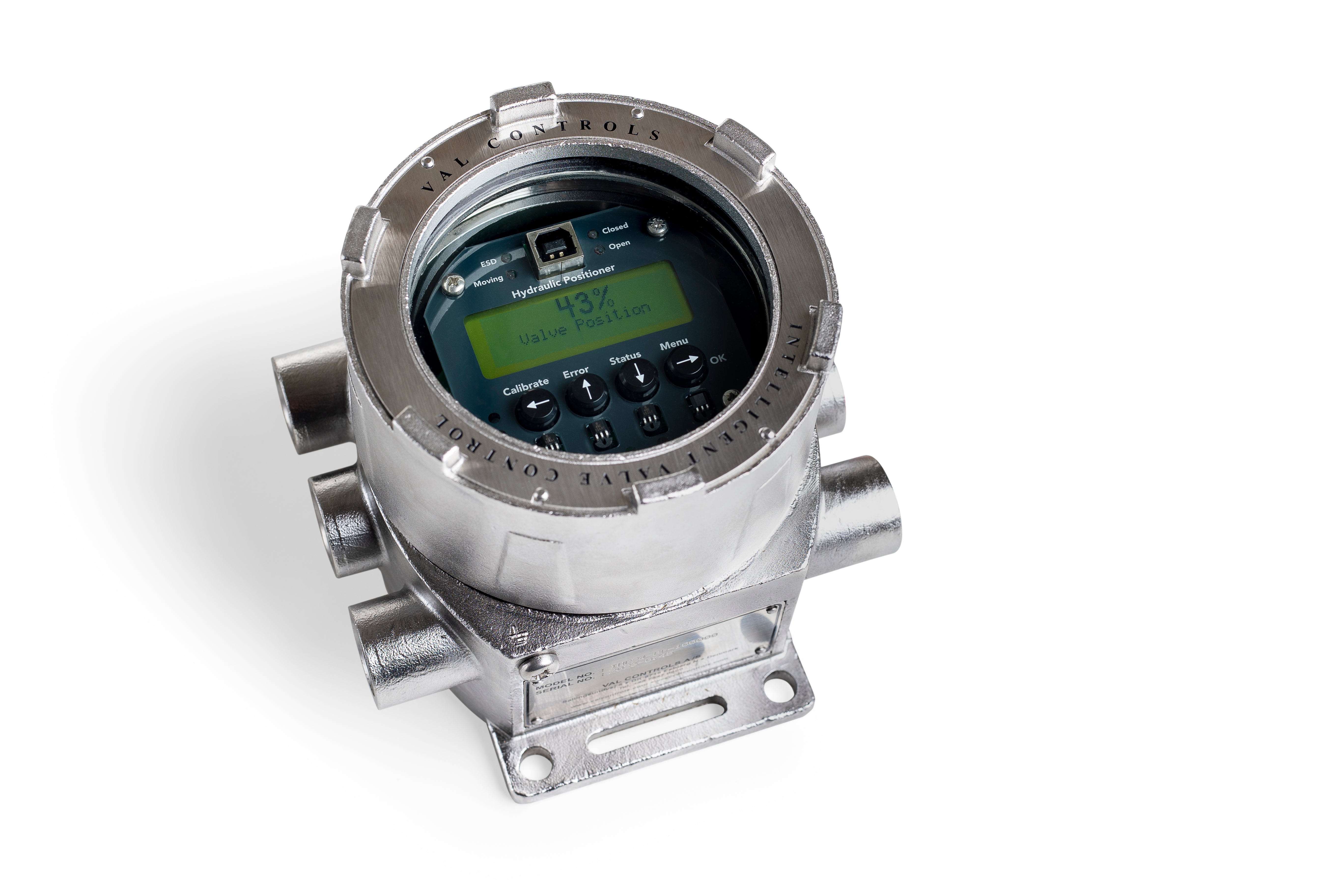

IHP24-AF

Flameproof positioner for proportional solenoid valve control.